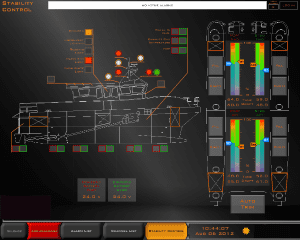

Ship trim and draught conditions can be easily evaluated and optimised using Servowatch’s new ServoTrim system

Servowatch, the marine systems integrator and automation specialist, has introduced a new trim and draught stability optimiser, ServoTrim, designed specifically to ‘balance the draught’ of SWATH (Small Waterplane Area Twin Hull) vessels.

The first ServoTrim system will be delivered to a Taiwanese shipyard for integration with a 22m wind farm supply vessel under construction for a UK-based operator.

Wayne Ross, Chief Executive Officer, Servowatch, said: “The need to calculate ship trim and draught is one of the most important measurements operators take to ensure vessel stability and safety. ServoTrim is designed to control a balanced draught for a vessel, providing automatic flow control after manual trim has been set.

“While the system is not a fully automatic dynamic stabilisation system, the system can be reset to automatically recognise the optimum trim and draught for different operational conditions, such as loading or unloading fuel, supplies and personnel.”

The ServoTrim installation for the SWATH wind farm supply vessel has been designed specifically for a four ballast tank configuration, with each tank fitted with a single sensor to provide concurrent tank, pump and valve status monitoring. Draught sensors are sited at each ‘corner’ of the vessel.

“Other types of vessels can benefit from ServoTrim, ” said Servowatch Systems’ Sales Director Martyn Dickinson. “It can be easily applied to inland waterway barges and heavy lift platforms. Certainly situations may exist where the platform needs a dedicated system which can provide a draught and trim correction function to counter uneven weight distribution.”

ServoTrim employs high-accuracy hydrostatic level transmitters to measure ballast tank levels and provide multi-port draught indications. To protect the sensors from external moisture, they are encased in IP68 and IP69K standard stainless steel housing.

TECHNICAL NOTES

Once the Servowatch ServoTrim system has been commissioned, the crew manually sets the trim ‘datum point’ when the vessel is at rest and the loading of fuel, commodities and personnel is complete and stable.

This is achieved by manually operating the ballast tanks fill and empty control system until the ‘correct’ trim is obtained. The data is then entered into the control system memory by selecting the automatic control function. The control system takes its reference signal from four draught sensors mounted within a vented pipe inside the vessel.

Each ballast tank is equipped with a level sensor to determine the depth of the water in each ballast tank. When the ‘automatic’ mode control is selected the ballast tank sensor data and the draught sensor data is fed into the control system to form a ‘datum point’ for each ballast tank.

The system automatically controls the water level in each ballast tank to maintain the vessel selected ‘datum point’ within the ‘dead bands’ of the control system. It automatically checks the ‘datum point’ every 10 minutes by comparing the actual draught level sensor signals with the draught level sensor signals registered.