CM Technologies (CMT) is advising shipowners and operators to urgently review their fuel and lubricating oil sampling practices following the entry into force of revised IMO guidelines.

Recent amendments to MARPOL Annex VI and SOLAS Chapter II-2 include a 50% increase in the required sample volume and stricter expectations around equipment, handling, and record-keeping.

The International Maritime Organization’s updated protocol, MSC-MEPC.2/Circ.18, mandates that fuel samples collected for MARPOL compliance now be a minimum of 600ml, up from the previous 400ml. This change ensures there is sufficient material to perform both sulphur content testing under MARPOL and flash point testing under SOLAS requirements. It also reinforces proper sampling procedures, including the use of tamper-evident containers, accurate labelling, and secure onboard storage.

“Sampling is often regarded as a technicality, but it is the foundation for effective compliance and dispute resolution,” said David Fuhlbrügge, Managing Director of CM Technologies. “Too often, we see crew improvising with makeshift containers due to a lack of proper gear onboard. Samples are often sent to labs in recycled beverage bottles – which can invalidate test results.”

Soft drink bottles frequently contain plasticizers – chemical additives designed to make plastic bottles flexible. These and other contaminants such as residual sweeteners, flavourings, or cleaning agents can alter the properties of the sample. This not only undermines test accuracy but can also lead to delays, re-sampling, or even the rejection of results by the laboratory.

“Labs may refuse to analyse non-compliant samples and, in some cases, will charge extra to transfer samples to proper containers, creating additional delays and cost,” said Fuhlbrügge. But beyond the laboratory implications, poor sampling practices can carry serious legal and commercial consequences.

“Proper sampling is not only about proving fuel quality but also about maintaining a defensible chain of custody,” he said.

Contaminated or poorly documented samples cannot be presented in bunker disputes or during Port State Control (PSC) inspections and any results labelled ‘indicative only’ would not be used to support compliance claims.

“With the new IMO regulations in place, ship managers and crews can’t afford to take shortcuts,” Fuhlbrügge furthered. “Proper sampling verifies that delivered fuel and oil conform to operational standards. If disputes arise, the integrity of that sample becomes critical. Any sign of tampering, contamination, or inadequate documentation could trigger fines, detention, or liability.”

The revised guidelines also transfer responsibility for tracking and storing MARPOL Delivered Samples from the ship’s master to the ship owner or management company.

“This shift underscores the importance of fleet-wide procedures and oversight,” said Fuhlbrügge. “Crews must be trained in how to operate sampling equipment, seal and label containers, and store samples correctly –typically for up to 12 months or until the fuel is consumed.”

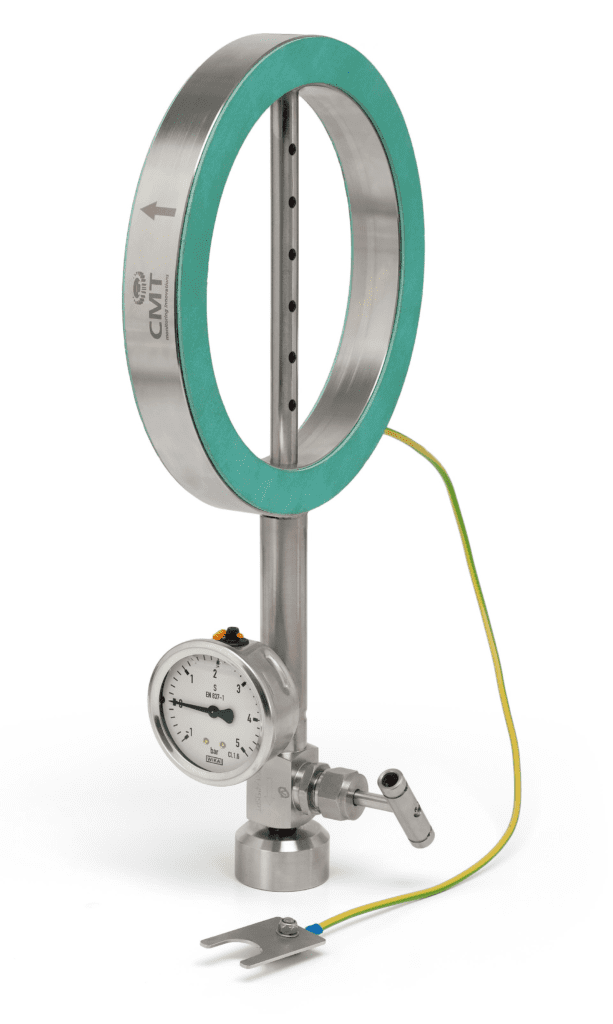

CM Technologies offers a comprehensive range of MARPOL-compliant solutions, including drip-type bunker samplers, certified sample bottles, tamper-evident seals, and lockable storage cabinets. The company is also preparing additional training resources and documentation to support shipowners and crew during the transition.

“The new sample volume requirement may seem minor, but it’s part of a broader shift toward stricter enforcement,” Fuhlbrügge said. “Authorities and labs are paying closer attention to how samples are taken and handled. Having the right equipment – and using it properly – is no longer optional. It’s a core part of regulatory readiness and risk mitigation.”

CMT believes these changes offer the industry an opportunity to raise standards, reduce risk, and improve transparency throughout the fuel supply chain.