Marine industry demand for fuel efficiency and sustainability is propelling enhanced fuel management techniques into the spotlight, against the background of a tougher regulatory framework. Inefficient fuel consumption drives up costs and on the macro-level undermines global and regional decarbonisation goals. Doing that the right way can even bring unexpected benefits – including repelling piracy, warding off fuel fraud, and keeping a firm eye on bunker quality.

One of the leading companies in marine fuel management, Texas-based Fueltrax, lays claim to running the first and most advanced electronic fuel management system (EFMS). In what it says is the only such system globally approved, vessel operators can monitor fuel consumption, access performance data, and optimise fleet operation from afar.

The company serves commercial marine operators, vessel owners, and charterers worldwide. Its offerings include fuel management systems, data-driven reporting, and fleet optimisation services. The client list is impressive: it includes Abu Dhabi National Oil Company (Adnoc), Aramco, Bourbon, BP, Grupo CBO, Chevron, Edison Chouest, ENI, Equinor, ExxonMobil, Mexmar, Nabors, Naviera Integral, Noble, North Oil Company, Oxy, Pemex, Petrobras, Petronas, Rawabi, Seacor, Shell, Tamrose, Tidewater, and TotalEnergies. This is a roster which continues to expand.

Fueltrax technology is used on more than 1,000 vessels and land installations, with key markets in the US Gulf, southeast Asia, West Africa, Latin America, and the Middle East. A prime sector benefitting from EFMS is that of offshore support vessels, where globally the fleet is ageing and requires a greater focus on performance and emissions. Fueltrax technology is suitable too for construction vessels, ships drilling for oil and gas, accommodation barges, and even FPSOs (floating production storage and offloading units).

Headquartered in Houston, Fueltrax’s leadership team comprises diverse expertise which it categorises as: “serial entrepreneurs, ex-military officers, Nasa flight controllers, seasoned energy executives, and engineers specialising in offshore automation and marine technology.”

The business originated in a client project by Control Dynamics International (CDI), an engineering company specialising in offshore automation and control systems. After completing the project, the directors of CDI “realised they had a unique product on their hands; one that had the potential to transform and modernise the commercial marine industry.” Spinning off Nautical Control Solutions from CDI in 2006, the drive began to develop and market the ground-breaking product.

Anthony George is founder and chief executive of Fueltrax. He began his control systems engineering career in 1988, and three years later formed Control Dynamics International.

Security is a big selling-point of the Fueltrax system, which it is said cannot be breached without immediately alerting the authorities. The company says: “A vessel protected by Fueltrax is a significant deterrent to malign activity because it provides crews with a cast-iron reason to comply.” Any pirates who attempt to hijack a vessel to steal its fuel “will always leave empty-handed because the crews cannot give them access to the fuel carried on board.”

Chain of custody fuel transfers are a contentious issue in the industry. A study in May 2022 (BIMCO-IBIA BL & MFM Survey Analysis) found that one in every 60 custody transfers end in quantity disputes, costing buyers an average of $27,790 per incident. This rate of altercation is blamed on traditional measurement practices producing inaccurate readings and creating opportunity for bunker fraud.

The Fueltrax technology not only records fluid quantity but can tell the difference between target fuel grades and contaminants such as water or waste chemicals and detect air bubbles in the flow – obliging suppliers to follow strictly the bunker delivery note.

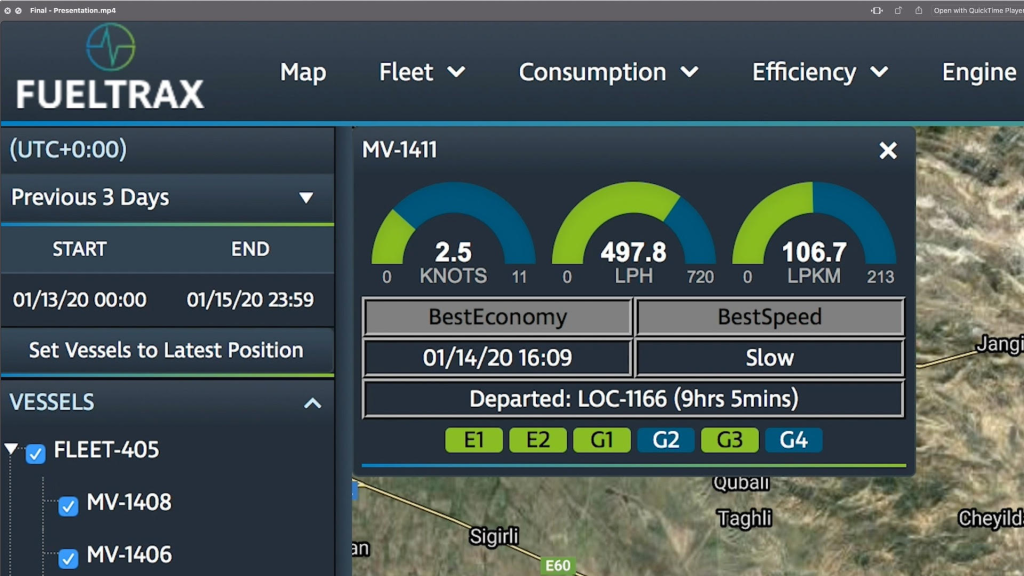

At sea, Fueltrax EFMS constantly monitors fuel consumption, ensuring that vessels are consuming exactly the right amount for the type of voyage. This benefits decarbonisation or lowering CO2 emissions by reducing fuel consumption using the optimisation throttle modes suggested by Fueltrax advanced analytics provided live at the bridge, where there is a display installed for the master. The optimisation modes are called BestEconomy and BestSpeed. Engine wear is reduced as well as yielding benefit to the vessel owner from the point of view of maintenance.

Any attempt to interfere with the system, or patterns of fuel consumption that deviates from expectations triggers an alarm notifying the operator.

Fueltrax has a role too in backing the Automatic Identification System (AIS), which it warns can be easily hacked or spoofed to provide false readings. If a crew manipulates AIS data to go ‘dark’, it usually means they are using a vessel for unscrupulous ends. A vessel making an unauthorised deviation could lead to allegations that the operator is involved in fraud, drug-dealing, human trafficking or other activities carrying criminal charges and heavy fines, and thereby, reputational damage. Every vessel with Fueltrax EFMS installed has its own dedicated, tamper-proof, hack-proof GPS transponder on board.

For increased situational awareness Fueltrax EFMS can be combined with Fueltrax Vison, a purpose-built and secure remote video monitoring system, which provides non-stop “eyes on board”, adding a further layer of visibility and security.

Fueltrax’s Active Fleet Management service gives 24/7 operational overwatch that puts the mariner team in constant contact with bridge and crew via the Texas operations centre and the regional vessel operations centres in West Africa, Southeast Asia and soon elsewhere. Enabled by the system are throttle and shaft power optimisation, reduced engine speed and other modes. Data-driven, real-time advice is provided to the bridge team to help them achieve best speed and best engine use for specific situations. This delivers measurable efficiency gains and allows ‘fuel-efficient’ behaviour to be rewarded to improve crew morale.

The company highlight its contribution to ESG (Environmental, Social, and Governance) compliance in monitoring crew working conditions, anti-corruption and ethics policies. This is critical at a time when ESG ratings are increasingly used by customers and investors to evaluate shipping company partners.

The overarching message is that investing in advanced electronic fuel management systems will yield long-term fuel savings – and more business opportunities through greater attraction to charterers.