There are several factors that make one coating easier to apply than another: the preparation required: the coating scheme itself – many layers of different types of paint, or one or two coats of a single product; minimum and maximum overcoat times; simple or complex spray equipment requirements; strict or lenient environmental conditions such as humidity and temperature. The overall speed of application is important economically because days can be added to time in the paint shop or in drydock.

The Ecospeed family of coatings

Coating scheme

In the case of Ecospeed coatings, the paint scheme is extremely simple. Two coats of the same product are applied to bare, prepared steel, aluminum, GRP or other substrate. There is no primer, no mid-coat, no tie-coat, no top-coat, no antifouling coating, no foul-release coating, no polyurethane. Whether one is applying Ecospeed, Ecoshield or Ecolock, the scheme is the same:

- A first coat of 500µm (20 mil) dry film thickness (DFT) onto the bare, prepared substrate.

- A second coat of the same product, also 500µm DFT. (A third coat can be used where an extended warranty and extreme durability are required).

Final DFT is usually 1000µm (40 mil) or, in the case of a third coat, 1500µm (60 mil).

That is all there is to it.

Preparation

Preparation of the substrate for Ecospeed, usually by grit blasting, is no different from that required of any high quality marine coating that is intended to last a long time without delamination.

- A roughness profile of at least 75µm (3 mil)

- Cleanliness of SA 2.5 or near white metal

Pitted or damaged surface

Ships that have been in service for some time with poor paint protection on the hull, rudder and running gear, are often pitted from cavitation erosion or general corrosion. Welding is used to repair this damage. When Ecospeed coatings are going to be applied to a pitted or damaged surface, it is far more efficient and economical to repair the surface using Ecofix, a filler specifically formulated to work with the Ecospeed coatings. Since it has the same basic chemical composition, Ecospeed can be applied one hour after the surface has been repaired with Ecofix. They bond perfectly and the result is a smooth, durable finish.

Environmental requirements

Ecospeed coatings have a relatively wide window for application. The humidity should not exceed 85%. Surface temperature must be between 0° C (32° F) and 60° C (140° F) and must be at least 3° C (5.4° F) above the dew point to prevent condensation from affecting adhesion.

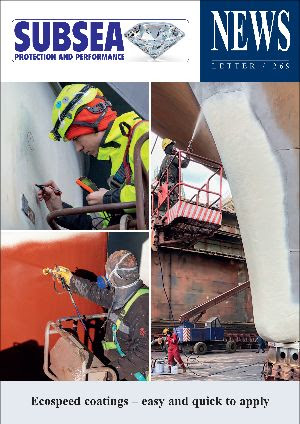

Equipment and personnel

Ecospeed coatings are generally applied with standard, single feed, airless spray equipment. A brush can be used for touch-up of small areas or for stripe coatings. The usual equipment found in any paint shop or drydock suitable for most marine coatings is used. There is no need for expensive, complex equipment such as dual hot feed spray. Application is done by the shipyard or paint shop’s regular applicators. No special training is required.

Ecospeed coatings in practice

Andi Hermans, Production Manager for Subsea Industries, oversees delivery and application of Ecospeed coatings. An AMPP certified coating inspector, Andi is often in the shipyards personally guiding and inspecting Ecospeed applications, and is very experienced in this regard. We asked Andi about the ease of application of Ecospeed coatings from a practical, hands-on point of view.

“When the application guide is followed precisely, it’s very straightforward and easy,” Andi says. “Take care with the mixing process and then just spray normally. Unlike with other coatings, if the thickness is too low or too high on the first coat, it is easy to remedy this. The inspector marks the areas that are too low or too high and when the next coat is sprayed on, the applicator compensates. That’s a huge benefit.”

“Some areas and circumstances make it difficult to control the wet film thickness,” he continues. “With Ecospeed, even if you spray on 1000µm wet film thickness, the paint will not sag. Another major benefit.”

“Ecospeed coatings are very easy to repair because you are only dealing with a single material, not different layers of different products. If you miss some spots or someone bumps his helmet on the flat bottom when the paint is wet, you can repair the spot with power tools and apply the second coat. Adhesion will be excellent and the repair will blend in perfectly.”

Andi explains that Ecospeed coatings lend themselves to very flexible application. “If you are in a hurry and have to paint a large area, you can have one team go ahead and paint the hull, and after a couple of hours the second team can start with the second coat. In this way you can fully paint a very large area in a single day. On the other hand, if you have to fit the painting in between other work but want to make sure the result of blasting is not lost with delays, you can apply the first coat and leave it like that for days while other work is done. Then the second coat can be applied. Any surface contamination can quickly be removed with pressure washing if needed.”

Ecospeed coatings only need to be applied once, and last the life of the vessel. When the ship comes back to drydock, any mechanical damage can be repaired easily and rapidly. “Just spot blast to ensure the necessary roughness and cleanliness in the area which needs to be repaired, apply two coats of the Ecospeed coating, and the damaged area will again look like new,” Andi concludes.

The end users’ point of view

Stephen Lee, former Senior Marine Engineer for British Antarctic Survey was in charge of replacing the ice breaking research and supply vessel RRS Ernest Shackleton’s underwater hull coating. He compares Ecospeed to other coatings, in this case for ice-going ships. “We required a paint system that was cost effective in purchase, application, and maintenance,” says Stephen. “Application of some of the more traditional icebreaker paint can only be done with a twin feed paint system which requires a great deal more care during the application process. You also have to ensure all the environmentals are correct, which can include tenting up space heaters around the area that is to be painted. The main, huge difference with Ecospeed is the lower cost and lack of complexity of application of the paint.”

“There’s a huge amount of preparation and logistics that have to go into getting the initial coat of traditional ice-going paint onto the hull, whereas with Ecospeed it’s minimal as long as you have a good paint inspector. And only minimum environmentals are needed.”

SICOR GmbH is a Hamburg based company specializing in corrosion protection in a variety of fields including ships and new ship construction. Coating the new hull of a large cruise ship in 2010 was the company’s first experience with Ecospeed. Reinhard Bachmann, Managing Director of SICOR summarized his company’s experience: “The application of the Ecospeed coating is simple to learn as long as you follow all the instructions in the data sheet. The product is, in my opinion, very easy to use.” In this particular project where the hull was coated in blocks at different shipyards, thousands of hours were saved in the application as a result of using Ecospeed rather than a conventional, multi-layer hull coating scheme.

Final words

The ease and speed with which Ecospeed coatings can be applied are an important added benefit to their high performance, durability and environmental safety