Following the slides presentation by Lars Odeskaug, Chief Operating Officer at Sevan Marine in Norway, at the RINA’s London branch event last Thursday 27 November 2014, one of the best ever events of its kind, we bring you an excellent account on the cylindrical hulls for FNLG.s by the speaker:

Background

In 2001 Sevan Marine was incorporated in Norway, to exploit the potential for a cylindrical hull for use in the oil and gas industry. Patents were filed and the meticulous work to design and analyse the motions of a cylindrical hull was initiated. The entrepreneurs in Sevan Marine carried out a series of model tests in the ocean basin at Marintek, Trondheim, Norway, and after tweaking of diameter, draft, Center of Gravity, Metacentric Height, etc., etc. they were eventually successful in having a cylindrical design with the necessary load carrying capacity and stability. An order for the first cylindrical FPSO was placed with Yantai Raffles in China, and before the unit was delivered a contract was secured with Petrobras for operations offshore Brazil. The unit is named Piranema Sprit and has been producing for Petrobras since 2007.

FPSO Pianema Spirit

Following the Piranema two more FPSO were built, the Hummingbird and the Voyageur, and both are currently in operation in the UK sector of the North Sea. Two more FPSOs are under construction, the Goliat at Hyundai Heavy Industries in South Korea, which will be the first FPSO in the Barents Sea, operated by ENI, and the Western Isles under construction at Cosco’s yard in Qidong, China, to be owned and operated by Dana Petroleum in the UK sector of the North Sea.

Four drilling rigs are also built with cylindrical hulls, The Sevan Driller and Sevan Brazil are both operating for Petrobras offshore Brazil, the Sevan Louisiana is drilling for LLOG in the Gulf of Mexico, and the last drilling unit, the Sevan Developer is at Cosco’s Qidong yard.

Finally, three accommodation units with cylindrical hulls are also under construction at Cosco Nantong, with delivery in 2015 and 2016.

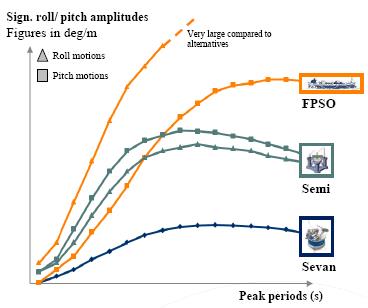

FLNG

There are more than 30 FLNG projects around the world in various stages of development, and the cylindrical hull concept offers several advantages over ship-shaped vessels and has the potential to enhance project development and economics. As the hull is cylindrical the vessel is geostationary and thereby eliminating the need for a turret and swivel, saving several hundred millions USD in investment and also significant operations and maintenance costs. The unit is developed with Dual Nitrogen Expansion liquefaction technology, but the hull is equally suitable for other liquefaction technologies. The cylindrical hull has less pitch and roll motions than a conventional ship shaped hull, and thus providing a more stable platform for the topsides gas treatment and liquefaction plant. With the large requirement for cooling water, up to 30 000 m³/hr, another important advantage is that seawater intake is a lot simpler without a turret, and the capacity for risers is typically larger than with ship shaped turret moored vessels.

Pitch and Roll motion comparison in irregular waves: Cylindrical vs. Ship Shaped FPSO and Semi Submersible

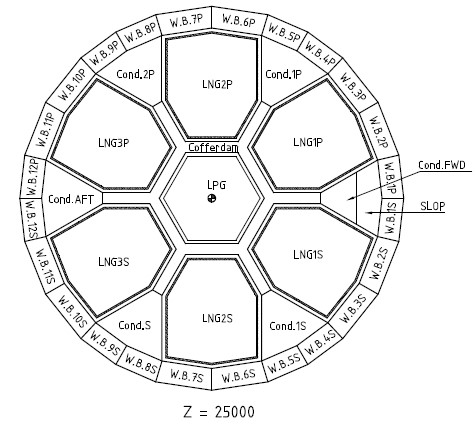

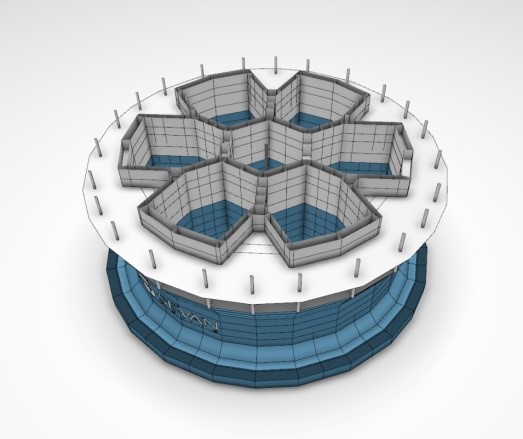

The cylindrical FLNG concept is a further development of the proven cylindrical FPSO design. The hull meets the requirements of the International Gas Code and has been developed to accommodate both SPB and Membrane cargo containment systems. With SPB cargo containment system the storage capacity is 170 – 190, 000m³, and with membrane system the storage capacity is 220 – 240, 000 m³. There is additional space for LPG and condensate storage.

Cargo containment lay-out

The hull has double sides and bottom, and the ballast tanks are in the double sides. The double bottom is void space. The condensate tanks are situated along the periphery between the cargo tanks. There are three decks, main deck, intermediate deck and the process deck. The cargo tanks extend all the way to the process deck, while the condensate tanks terminate at the main deck. The process deck is supported from the main deck by columns and bulkheads.

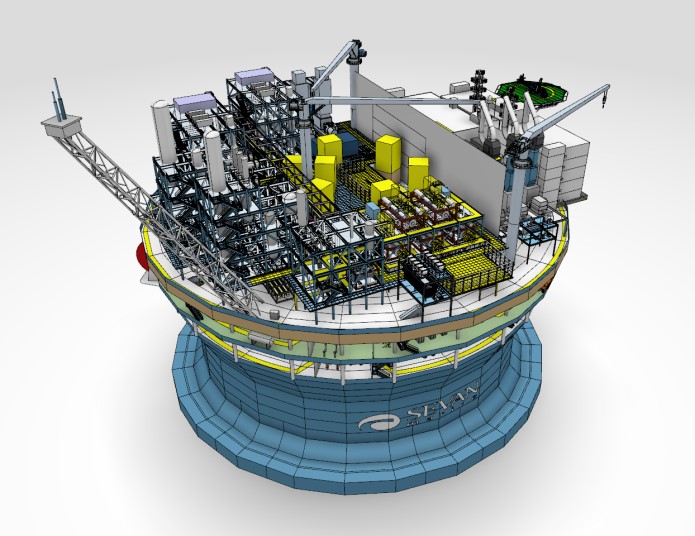

Hull design

Hull design

Utility and safety equipment, such as lifeboats, water-makers, heat exchangers, etc. are located on the main and intermediate decks. The gas pre-treatment and liquefaction plant along with power generation and living quarters are on the process deck. The living quarters have 120 beds in single cabins and there are three cranes for material handling. Total topsides weight is about 32 000 tonnes.

Cylindrical FLNG

Offloading is a challenge for many FLNG projects. Side-by-side offloading is only possible in benign areas with sea-states below Hs 2 m. Tandem offloading increases the operational threshold, but it also means the introduction of dedicated specially equipped LNG carriers with Dynamic Positioning (DP2) capabilities at significant extra cost to the project. A novel development, the HiLoad, could resolve the issues with offshore transfer of LNG. The HiLoad unit is a specially designed vessel that attaches to the LNG carrier and guides it during approach and departure and keeps the LNG carrier at a safe distance of 200 m from the FLNG during the offloading operation. The first HiLoad is in operation offshore Brazil for offloading of crude oil, and the LNG version will be available with cryogenic floating hoses in 2015.

Cylindrical FLNG with HiLoad offloading

Based on the experience gathered from the cylindrical FPSOs and Drilling units currently in operation, and the development work that has been carried out for the cylindrical FLNG solution, this technology is now at a stage where further design and engineering should be carried out on a specific project with specific metocean conditions and a defined gas composition.

Conclusion

The cylindrical FLNG solution offers a stable platform for gas pre-treatment and liquefaction and eliminates the need for costly turret and swivel arrangements. In combination with the HiLoad for offshore LNG transfer it offers a safe, reliable and cost efficient solution to the emerging FLNG market.